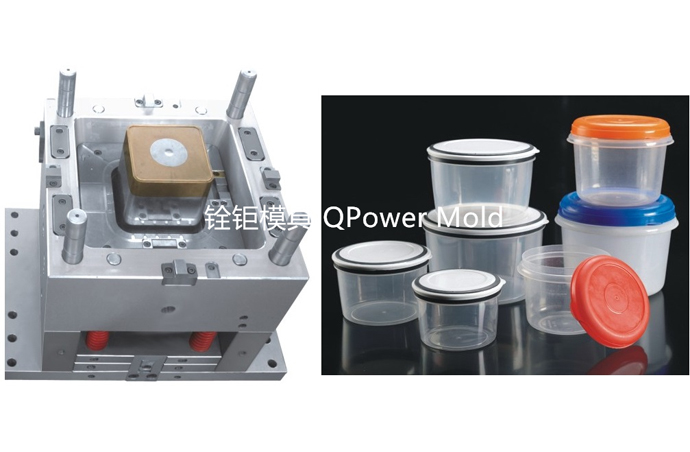

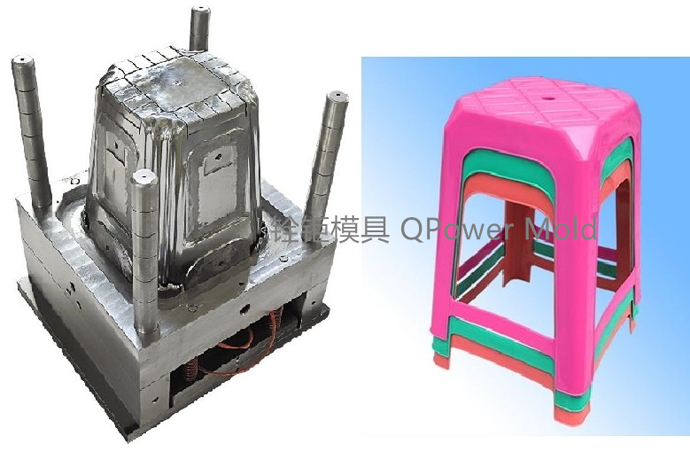

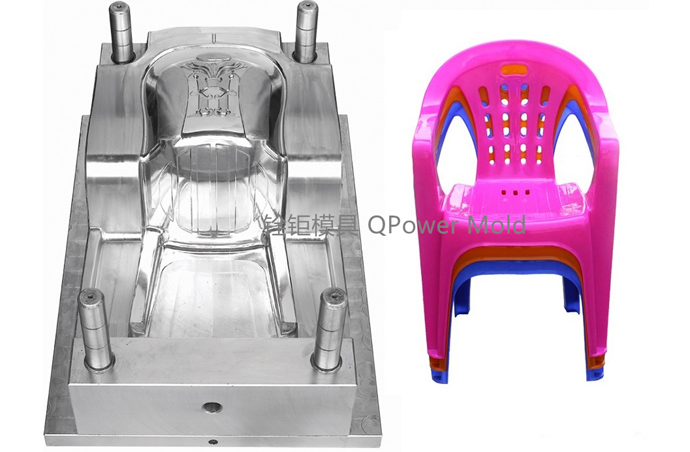

Daily necessities mold

Advanced CAD / 3D technology is used to assist in the design of the mold structure. The rationality of the structure is very important to the performance and service cycle of the mold. A reasonable mold structure can not only improve the production efficiency, but also greatly improve the service cycle of the mold. The mold is made of high-quality special mold steel such as S136, 718, and P20. Using high-precision CNC machine tools to precisely process each part of the mold, to ensure that each part of the mold achieves precise coordination, effectively reducing the failure rate of mold use, excellent mold cooling system design, so that the mold has efficient cooling performance, effectively ensuring The molding aesthetics of plastic products reduces the molding cycle time of the mold and greatly improves the production efficiency.