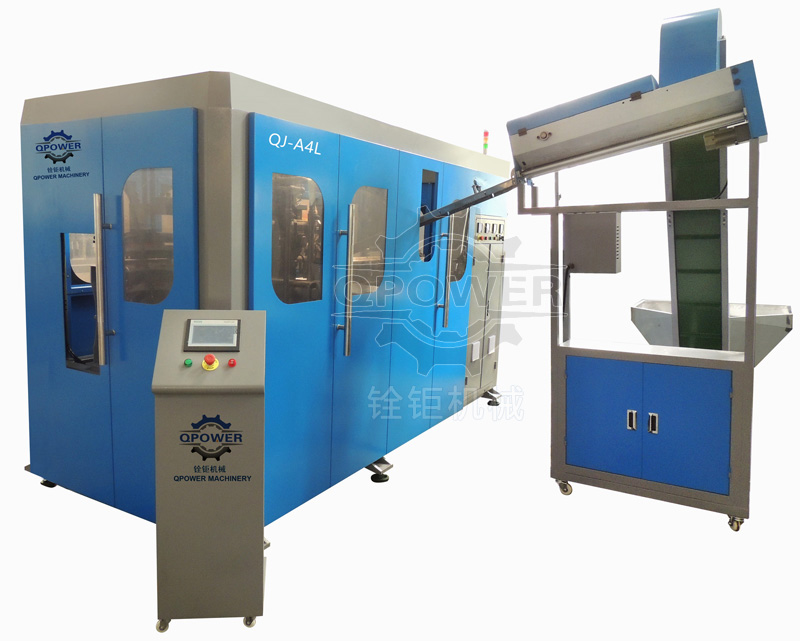

QJ-A4L Servo Automatic Blow Molding Machine

Illustrate

QJ-A4L series servo automatic blow molding machine has a maximum output of 7000 bottles per hour, which can be directly connected to the filling equipment without the need for a bottle unscrambler. This model has the advantages of accurate positioning, low power consumption and fast speed. It is suitable for the production of carbonated beverage bottles, juice beverage bottles, mineral water bottles, cosmetic bottles, edible oil bottles, medicine bottles, daily chemical bottles, beer bottles and other packaging containers of any shape below 2 liters.

QJ-A series linear servo features:

● QJ-A Servo Automatic Blow Molding Machine runs at high speed, stable and precise positioning. It adopts advanced microcomputer PLC control system, which has the advantages of high control precision, fault self-diagnosis, intelligent monitoring, data management, fault display and so on.

● Intensive centralized heating design, small spacing between heated preforms, which can reduce electricity consumption by 30% and heat the preforms more even.

● The servo system is used to control the operation, with high movement positioning accuracy, fast operation speed, better stability and reliability, and longer service life .

● Infrared lamps are used for heating, with strong light penetration, and the width and height of lamps and reflectors in the heating area can be adjusted Adjust to suit the heating of preforms of different structures.

● Wide range of bottle types, meeting the production needs of most customers.

● Each mechanical action has a safety self-locking device. When a process fails, the program will automatically switch to a safe state .

● The production process is all automated, which has the advantages of low investment, high efficiency, convenient operation, simple maintenance and safety.

● With quick mold change function, it only takes 20 minutes to change the mold.

| items | Unit | QJ-A4L-1S | QJ -A4L-2S | QJ-A4L-3S |

|---|---|---|---|---|

| Material | / | PET | PET | PET |

| Cavity | Cavity | 4 | 4 | 4 |

| Maximum volume | L | 2.0 | 2.0 | 2.0 |

| Max Neck Size | mm | 42 | 42 | 42 |

| Maximum Diameter | mm | 120 | 120 | 120 |

| Max bottle height | mm | 430 | 430 | 430 |

| Theoretical Output | BPH | 4500-5000 | 5000-5500 | 5500-6000 |

| Low Pressure | MPa | 0.8 | 0.8 | 0.8 |

| High Pressure | MPa | 3.0-3.5 | 3.0-3.5 | 3.0-3.5 |

| Total Power | KW | 72 | 72 | 72 |

| Use Power | KW | 50 | 50 | 50 |

| Voltage/Frequency | V/Hz | 220-380/50-60 | 220-380/50-60 | 220-380/ 50-60 |

| Blowing machine size | M | 3.75 x 1.6 x 2.7 | 3.75 x 1.6 x 2.7 | 3.75 x 1.6 x 2.7 |

| Blowing machine weight | Kg | 4500 | 4500 | 4500 |

| Preform Feeder Dimensions | M | 2.13 x 1.4 x 2.7 | 2.13 x 1.4 x 2.7 | 2.13 x 1.4 x 2.7 |

| Preform conveyor weight | Kg | 500 | 500 | 500 |