PET bottle plastic bottle

Illustrate

Bottle Design

QJ has extensive design experience and can transform your imagined bottle concept into a real bottle. QJ uses the international advanced 2D&3D software to design the appearance of the bottle, which meets the shape design requirements of various bottle types in today's market.

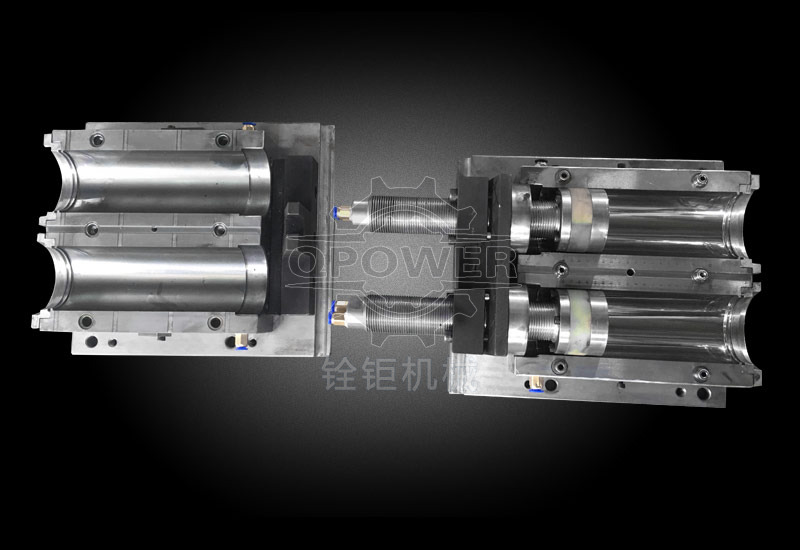

Quality material

50 carbon steel is the standard material for making blow molds because It is easy to machine after forging. At the same time, we also provide 7075 type magnesium-aluminum alloy materials to make molds. 7075 magnesium aluminum alloy is commonly known as aviation aluminum. Compared with other aluminum materials, it has higher hardness and density. It is an ideal high-end material for making bottle molds. The mold will never rust. It is especially suitable for countries and regions with hot weather. service life. The mold used in the automatic blow molding machine is usually made of 7075 magnesium aluminum alloy. This material can provide better cooling effect to achieve rapid prototyping, and the mold is light in weight and convenient for mold replacement.

Processing equipment

For different bottle types, QJ uses different processing equipment The mold is processed and manufactured, such as 3-axis machining center, high-speed Jingdiao machine tool and other professional processing equipment to ensure the quality and precision of the blowing mold, so that the competitiveness of the QJ series blowing mold in the same industry is enhanced.