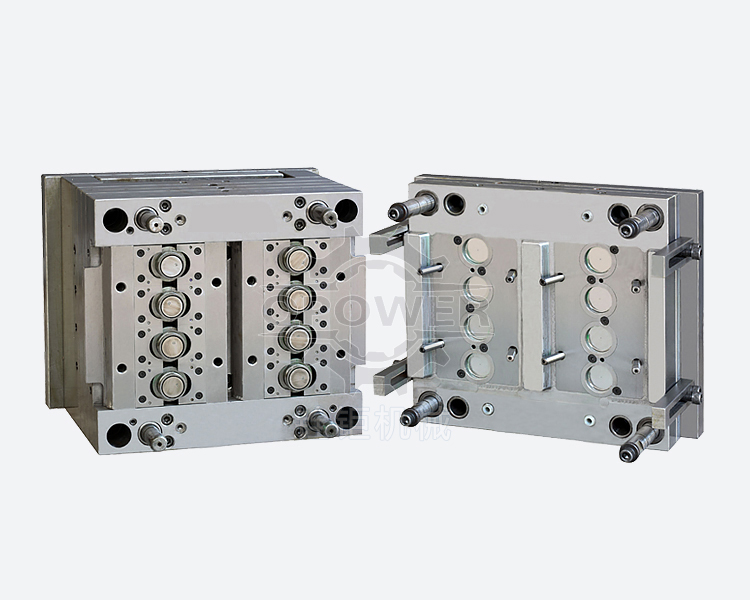

8 cavity water bottle cap mould

Illustrate

Cap design

We use advanced 2D&3D software to design bottle cap moulds, experienced designers and advanced design tools make QJ Have the ability to translate your bottle cap design ideas into reality to meet your finished product requirements.

Hot Runner System

QJ series bottle cap injection mold adopts hot runner system with superior thermal conductivity. The heat conduction is fast, and the temperature can be quickly heated during the manufacturing process of the bottle cap to achieve the ideal heating effect. There is a micro nozzle in each cavity of the hot runner cap injection mold, which ensures a large injection flow and a small cap connection point.

Steel and Machining Tools

QJ bottle cap injection mold is made of high-quality steel. In order to meet different processing requirements, different mold steels are also used to make cores, mold cavities, guide posts, mold bases, etc. High hardness and good processing performance are the advantages of the above steels. CNC machining centers, high-precision coordinate boring machines, and high-pressure EDM molding machines ensure accurate machining and high-quality finished products.

Quality Monitoring

We pay great attention to the structure of the cap and the design of the thread. During the manufacturing process, we use the most suitable processing technology and processing equipment to ensure the accuracy and clarity of the thread. After the mold is assembled, multiple tryouts are performed to ensure that the mold can achieve the best performance.